KINGDA PUMP GROUP

Kingda pump group Xingtang Pump Co., Ltd

Kingda pump group Xingtang Pump Co., Ltd. covers an area of more than 300 mu, with a total construction area of more than 80000 square meters. It can produce 10000 sets of industrial impurity pumps such as slurry pump, dredging pump, desulfurization pump and shield pump, and 2800t of pump accessories. The company strives to integrate the upstream and downstream industrial resources of the impurity pump industry in the region, and gradually form a impurity pump R & D, design, manufacturing and sales base with Kingda pump group Xingtang Pump Co., Ltd. as the industrial core and green manufacturing and intelligent manufacturing as the development direction.

Kingda pump group Xingtang Pump Co., Ltd. inherits the strong R & D and manufacturing capacity of the group company, and innovates and constructs four platforms on the original basis, one is green design platform, the other is green manufacturing platform, the third is green test platform, and the fourth is green pump product life cycle analysis and management platform. 【Detail】

KINGDA MANUFACTURE

Strong manufacturing and R & D capabilities

The company has always attached importance to the construction of scientific and technological innovation team and the cultivation of medium and senior innovation talents. In the fields of fluid machinery and engineering machinery, there are 30 people with senior professional titles, 55 people with intermediate professional titles, 30 people with primary professional titles, 56 people engaged in R & D of scientific and technological projects, and strong scientific research strength, which provides sufficient technical guarantee for the continuous innovation and upgrading of the company's leading products, the gradual improvement of production and marketing volume, occupying the forefront of the industry market and further expanding brand awareness. The products of our group company have been rated as the preferred energy-saving products and recommended products by the Ministry of science and technology, the Ministry of construction, the Ministry of machinery industry and the State Bureau of technical supervision. 【Detail】

KINGDA HONOR

National high tech enterprise

Strong pump group Xingtang Pump Co., Ltd. is a national high-tech enterprise, a green factory in Hebei Province, A-level R & D organization of industrial enterprises in Hebei Province, an enterprise technology center in Shijiazhuang, a technological innovation center in Shijiazhuang, and a science and technology enterprise in Hebei Province. The group company is the director unit of the pump branch of China General Machinery Industry Association, the director unit of China Dredging Association and the member unit of the national pump Standardization Technical Committee. It has passed the type certification of marine pumps by China Classification Society; In May 2020, it passed the ISO9001 quality system certification of Huaxin Technology Inspection Co., Ltd. and American FMRC company; Passed the safety assessment and environmental assessment certification in June 2020; In just over a year since it was completed and put into operation, it has 20 authorized patents and 16 accepted patents. 【Detail】

Solutions for mining and metallurgy

KSH (R) series heavy duty slurry pump, ZGB (P) series high lift slurry pump

KSL series light slurry pump, KSF, KSHF series foam slurry pump, KSS (R) series slurry pump

Solutions for flue gas desulfurization industry

TLR series double shell desulfurization pump, TL series single shell desulfurization pump

Environmental protection dredging solutions

Wn series dredge pump, wnq series underwater dredge pump

QDP series submersible sand pump, G, GH series gravel pump

Tunnel excavation solutions

KSG series slurry discharge pump, ksgh series slurry discharge pump

Mine metallurgy solutions

KSH (R) series heavy duty slurry pump, & nbsp; ZGB (P) series high lift slurry pump, KSL series light slurry pump

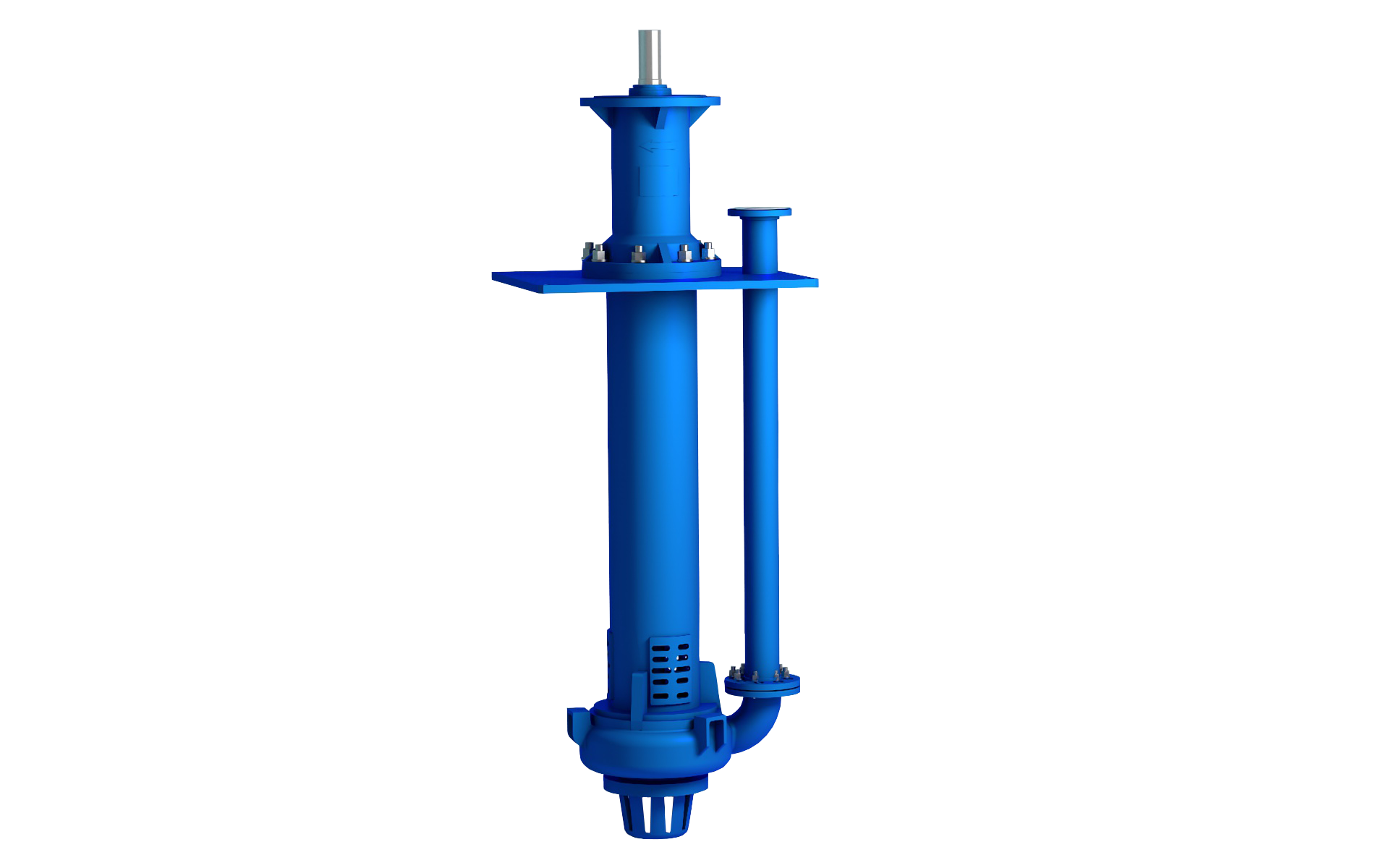

KSF、KSHF系列泡沫渣浆泵、KSS(R)系列液下渣浆泵

NEWS CENTER

KINGDA

Leading brand of impurity pump

Facing the international market and continuing and further expanding foreign sales business, it has established technical cooperation and business contacts with more than 60 foreign companies……

KINGDA

Leading brand of impurity pump

Facing the international market, it has established technical cooperation and business contacts with more than 30 foreign companies, and its products have been exported to more than 60 countries and regions……

Kingda pump group Xingtang Pump Co., Ltd

Kingda Pump Industry Group Co., Ltd

Add:Xingtang County, Shijiazhuang, Hebei, China

Tel:0311-85426662/6661

Fax:0311-85426671

Mail:info@kingdapump.com

SEO TAG